After the printer parts were ordered for printing, a revision of the design happened, and I ended with an "old" idler part for the extruder. I made do by gluing some pieces of ice-cream cone stick to the sides, and awaiting for my printer to be operational to print the new version.

This is now done!

But I'm getting ahead of myself. Let's take things in order.

First, I decided to print a calibration part from Thingiverse (

http://www.thingiverse.com/thing:1637 ) :

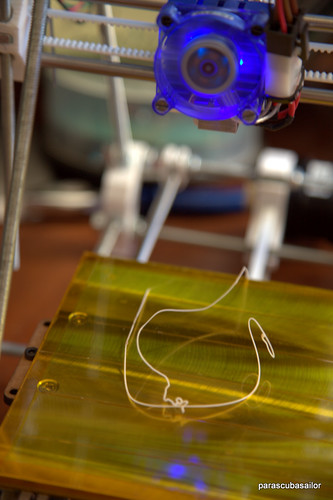

The first attempt is on the right. I started with the head too far away from the build platform, and the first layer did not stick properly. Obviously, when dropping the bed down for the second layer, there was no chance of things improving. I let if print a few more layers, and then restarted the print.

On the second attempt, I paused the print after the printing of the "skirt" around the part, and adjusted the height of the Z axis so the head was about two tenths of a millimeter away from the bed. That seemed to be the correct height, and the first layer was laid down correctly. The print ended without drama.

After lunch, I decided to print the new version of the extruder idler. I first downloaded the stl file from the Git repository, rendered it using Skeinforge and started printing. After a short while, something looked odd. It appeared as if the Y axis had not completed a movement, and everything above that level was offset on the Y axis. Then the print stopped abruptly, the printer stayed motionless, and the Pronteface program hung on the notebook. I'm not sure if the printer hanging caused the program to hang, or the reverse...

Back to the drawing board. Sort of. Just a plain restart of the print. This time, I decided to print from the SD card. It was simple enough to copy the .pla file to the SD micro card on the other notebook, put the card in the card reader on Bertie, and select the print from there.

About half way through, the X skipped some distance, and everything from there got shifted. I stopped it then. No point in wasting material.

On the third try, the tubing that leads the filament between the extruder and the hot end came off the fitting. Obviously, no material was being extruded, so I stopped the print once again. I suspect the printing temperature dropped too much with the quantity of material that has to be heated up, increasing the extrusion pressure, so I decided to lower the speed and increase the hot end temperature.

On the following try, I obtained a part of a quality acceptable for a replacement of the "old" idler.

Tomorrow, I'll order material from Faberdashery and from China, so I can compare the delivery times, prices and material quality.

The wind has turned Southerly. That might not be relevant for most RepRapers out there, but it is for paragliding pilots. When there's no paragliding, other activities come to the fore!

After much software fiddling, in particular installing the package several times on Ubuntu to get the optional buttons to appear, (Note: it's important to check in which directory the program gets started, as it creates a .pronsolerc in the Home directory, which, if you forget to delete it, makes the buttons not appear), I managed to get the software to run, and activate all the functions on the printer.

At first, a few of the motors wouldn't move. I double-checked the current limit values (400mV on all drivers, and I set the Z to 800mV, as there are two motors). Nothing amiss there. I powered off, moved them by hand to check that there was no mechanical snag, nothing wrong there either.

After powering on again, everything went fine! This type of troubleshooting is very unsettling to me. How am I going to fix it next time if I don't know what I did to fix it this time?

I measured the temperature wherever I could stick the thermocouple probe and compared the readings from my hand-held meter with the values displayed on the computer screen. Not bad. There are at most a few degrees deviation, and that can easily be explained by the difficulty in holding the mobile probe on the right spot, the poor thermal contact, and the cooling effect the probe has on the small part (on the hot end in particular).

The pyrometer gave me a reading of the bed surface that was in agreement with the hand-held thermocouple, and a few degrees lower than the computer reading. That also ties in.

Next, I measured the feeding of the filament. For a 10mm Extrude command, 11.5mm of filament is pushed in. I had reservations about the strength of the extruder motor, but after the little testing I have done, I fully trust that the hobbled shaft is able to push the filament (and pull it from the spool) without problem.

Next step is the calibration, and setting the parameters to have as good a print finish as possible...

Oh, and the printer got a name: Bertie. It's going to free me from having to purchase plastic parts that don't serve my purpose 100%, it's Huxley-Bertie.

The wind has turned Southerly. That might not be relevant for most RepRapers out there, but it is for paragliding pilots. When there's no paragliding, other activities come to the fore!

After much software fiddling, in particular installing the package several times on Ubuntu to get the optional buttons to appear, (Note: it's important to check in which directory the program gets started, as it creates a .pronsolerc in the Home directory, which, if you forget to delete it, makes the buttons not appear), I managed to get the software to run, and activate all the functions on the printer.

At first, a few of the motors wouldn't move. I double-checked the current limit values (400mV on all drivers, and I set the Z to 800mV, as there are two motors). Nothing amiss there. I powered off, moved them by hand to check that there was no mechanical snag, nothing wrong there either.

After powering on again, everything went fine! This type of troubleshooting is very unsettling to me. How am I going to fix it next time if I don't know what I did to fix it this time?

I measured the temperature wherever I could stick the thermocouple probe and compared the readings from my hand-held meter with the values displayed on the computer screen. Not bad. There are at most a few degrees deviation, and that can easily be explained by the difficulty in holding the mobile probe on the right spot, the poor thermal contact, and the cooling effect the probe has on the small part (on the hot end in particular).

The pyrometer gave me a reading of the bed surface that was in agreement with the hand-held thermocouple, and a few degrees lower than the computer reading. That also ties in.

Next, I measured the feeding of the filament. For a 10mm Extrude command, 11.5mm of filament is pushed in. I had reservations about the strength of the extruder motor, but after the little testing I have done, I fully trust that the hobbled shaft is able to push the filament (and pull it from the spool) without problem.

Next step is the calibration, and setting the parameters to have as good a print finish as possible...

Oh, and the printer got a name: Bertie. It's going to free me from having to purchase plastic parts that don't serve my purpose 100%, it's Huxley-Bertie.